Boiler Exchange 2007 - 2010

chronicle

19th April 2007

After 50 years the type approal certificate of the boiler has expired. As stated in the inspection report of the TÜV: "The boiler is suffering of material fatigue, it has reached the end of it's life span. The deformation of the boiler is becoming a problem and can not be controlled anyfurther. Therefor the boilder has to be decommissioned."

19th Oktober 2007

A feasibility analysis is prepared. A new boiler plus installation, additional neccessary equipment plus shipyard costs will sum up to about € 150.000,-.

As a requirement the new boiler has to be manufactured according to the old specifications.

23rd April 2008

A fund-raising campaign is initiated by CARL ROBERT ECKELMANN and the first € 1000,- are transfered to a separate bank account to finance a new boiler. Within one year donnations of around € 60.000,- can be accumulated from around 100 Donors.

4th Oktober 2008

Claus D. is transfered to the shipyard M.A. Flint where on the slip the underwater coating is renewed. On Nov 18th the ZSUK (classification authority for inland navigation vessels) is certifying the hull to be without any defficiencies.

17th Oktober 2008

Doomsday: During a meeting in the Döns (historical watining house at the Museumshafen) Mr. Udo Puchert, engineer from PROKON Nord Energysystems, Mr. Wolfgang Hoffmeister, CEO of UHLIG Rohrbogen and Mr. Andreas Westphalen, engineer from WULFF Engineering & Service Hamburg are aggreeing on the construction, production and planing of a new boiler. Planning and Project Management are to be free of charge. Everthing agreed be handshake and without any further obligations. The only requirement: NO fixed date. Claus D. will sail again!!

7th January 2009

On board preparation works are starting, all pipes and fittings are dismantled by a crew of volunteers. Hard work in confined space.

10th June 2009

Within three days the superstructure is dismantled at the Norderwerft and the old boiler with a weight of 8mt is removed. The 5 x 6 m hole in the deck is covered by tarpauline as a provisional solution. Afterwards Claus D. is transfered back to the Museumshafen and remains there as a floating work in progress exibition.

Nordwerft 6/12/2010.

Fotos Sven Albrecht

26th June 2010

Project Meeting of all involed persons at UHLIG Rohrbogen in Langelsheim.

The flue pipe is completed, the two boiler heads are ready. All manufactured according to the old designs.

5th October 2009

The TÜV Nord is approving the construction and design of the new boiler. The construction of the new boileer has been more complicated and time consuming than planned as it is a reconstruction based on plans from 1957 with modifications to present regulations. With the approval of the design and the plans the final construction can continue.

4th November 2009

The new boiler is taking shape. Flue pipe, return chamber (if that is the correct English term???), the boiler heads are installed and now it is the time of the welders.

23rd November 2009

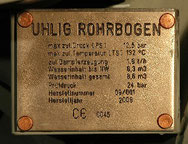

With 40 selected guests and under supervision of the TÜV the new boiler is pressure tested with 24 bar. The boiler with the construction number 09/001 is ready for on board installation. The last part is the traditional ceremony of engraving and mounting the manufacturers plate. A few days later the boiler is sandblasted and painted with a heatresistant two-component paint by BAKE Surface protection free of charge.

22nd December 2009

Towards the end of the year a good progress is made. The smoke box is mounted, the SAACKE Burner is in place, boiler insulation is done bei G+H, the flue pipe is fitted with charmotte by JÜNGER + GRÄTER and the fittings by ARI + GESTRA FITTINGS are in place. All high quality products as donations in kind.

23rd February 2010

The boiler is ready for delivery. A classic ship boiler of scottish design, looks like in the textbook.

1st March 2010

As oversize and heavy lift transport the boiler is delivered to Hamburg and stored in the warehouse of the Norderwerft. Meanwhile Claus D. is transfered again to the shipyard M.A. Flint for Bilge cleaning and renewal of the bilge and engine room coating.

29th March 2010

The big day: Under close observation of numerrous guests the new boiler is lifted into the hull and the ship reassambled. After almost one year Claus D. is finally a real ship again. In the following two weeeks the company KNAACK + JAHN is reinstalling all piping systems in the engine room and the whole deck is repainted by KOCKS.

18th April 2010

After three weeks in yshipyard Claus D. is proceeding under tow hopefully for the last time to Harburg. JUGEND IN ARBEIT will do all the remaining works. Between 1995 and 1998 Claus D. was already once restored at the same place. Now the burner control, all electrical installation, cabeling is done by Jugend in Arbeit. Parallel the deck crew is preparing the ship to carry guests.

31st May 2010

After a comprehensive check of all documents and a visual inspection on board the city of Hamburg is giving the official permission to run and operate the boiler.

11th June 2010

After comprehensive checks in cold condition the burner is ignited in presence of representatives of SAACKE and the TÜV. The rotary cup oil burner SKV was converted according to historic designs. Fuse ignition and manual control. The boiler and the burner correspond to the technique of the 1950s but with all safety features of 2010.

12th June 2010

The boiler is slowly heated up and step by step the whole system is put under steam without any big problems.

19th July 2010

Final inspection by the TÜV without deficiencies. Claus D. is allowed to steam again!!

21st July 2010

Final inspection of the ZSUK, Claus D. is receiving it's certificate of class.

30th July 2010

Transfer of Claus D. from Harburg to the Hafencity via Oevelgoenne. Three days open ship as part of the maritime bazar "Tüdel un Tampen" at hte Hamburg Cruise Days.

6th August 2010

After 4 years out off service 150 guests on board of the TIGER, the WOLTMAN, the FEUERWEHR IV and the ALEXANDRA are welcoming Claus D.